Semi-professional edge banding users are those who plan to use the machinery for four hours per day on average. Powerful high-frequency motors would be an excellent choice in this category. For many years, machines were built primarily with belt drives and standard frequency motors. At the moment, the three most common edge banding processes are EVA edge banding, PUR edge banding, and laser edge banding.

Optical Edge Banding Machine

Check to see if the edge banding equipment is operational. On the control panel, select the relevant functions. In the bedding industry, a tape edge machine is a type of sewing machine used to finish the top and bottom edges of a mattress. The machine is used to sew the top and bottom panels of a mattress to the mattress edge and cover the raw edge with protective tape or ribbon. Some tape-edge machines are fully automated, capable of turning corners and flipping mattresses without the operator’s intervention.

It also comes in a variety of thicknesses, so it’s critical to use the right one for the job. To account for this, some astute individuals devised technologies that allow you to glue different bands of glossy finished material to those rough edges in order to match the tops and sides. The XB is the smallest machine in the range, designed for small spaces and ideal for the craftsman and artisan industries.

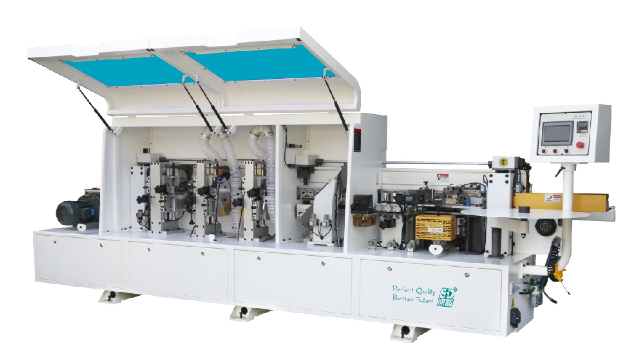

In recent years, Blue Elephant has upgraded its wood banding machine product line several times. We have also released a number of edge bander models for sale in order to meet the processing requirements of domestic and international panel furniture manufacturers. The main structure, multiple processing units, and the control system comprise a cabinet edge banding machine. The pre-milling unit, banding tape conveying unit, banding unit, cutting unit, trimming unit, rounding unit, scraping unit, and polishing unit are among the processing units.

How To Select Banding Machine

When you’re selecting your residence hall furniture and determining the specifications, you’ll inevitably decide on the materials you want. Position indicators allow for very simple precision adjustment of trimming cutters. The copiers in the unit are bearing mounted to ensure smooth panel feed. The use of compact and powerful high frequency motors ensures the best finish on the top and bottom edges.

However, its adhesive is stronger and its glue line is thinner than that of EVA banding. Furthermore, the amount of banding used for the same board is less than half that of EVA banding. EVA glue is inexpensive and has few requirements for the banding machine and working conditions. More than 85% of whole-house custom furniture factories currently use EVA to band the edges because it is simple and inexpensive to produce. It is used to band various types of wood and banding tapes. If the speed of the glue shaft is high, the speed of glue application will be high.

PVC edge banding tape is manufactured using a PVC edge tape machine with a double screw extruder. Change the mould for different sizes of edge banding. This machine can have two, four, six, or eight cavities. The width of the edge banding is 19mm-54mm and the thickness is 0.4mm-2mm. SCM edge banders and squaring-edge banders are well-known throughout the world and are one of the Group’s main strengths.

This brand, with its long history, is now known as a model name. GLUE UNIT Gluing unit for edges up to 80mm high, with melting and polyurethanic glue tanks, as well as the corresponding pre melting devices. It can ensure maximum machine finishing quality by using intensive units with high-speed motors. It is simple to use and maintain, requiring no special training.