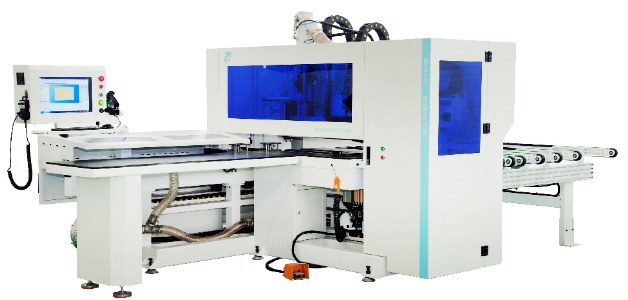

The CNC nesting machine with row drill is a type of wood cutter drill machine that is used to cut and drill customised panel furniture. When compared to traditional sliding table saws and electronic cutting saws, the CNC drilling cutting machine can eliminate the labor-intensive traditional cutting mode. While cutting the material, it can also perform vertical CNC drilling. Intelligent production is truly realised when combined with dedicated production design software.

Components of Drill

Fittings are any metal components that are screwed onto a piece of wood. Hinges, handles, adornments, and other mechanical components are commonly attached with short wood screws. The hinge boring machine can follow bore hole patterns and insert the necessary parts into the workpiece. Individual drilling heads can be independently and consistently adjusted, and the machine can process any number of workpieces in a series to a consistently high quality.

This, like the winding mechanism, is prone to wear and tear and will not last indefinitely. It is common for the carbon brushes to be worn out and the capacitors to have blown before the motor itself becomes unusable. Fortunately, both are wear parts, so replacements will be simple to find. Installing the appropriate drill and securing the specified material to the table are typical steps in setting up a CNC drilling machine for wood. SCM CNC drilling centres are the ideal solution for batch-one production. High-quality drilling, grooving, and routeing processes are possible in stand-alone, unattended, or plant-integrated solutions.

Innovative technologies for wood milling, boring, cutting, and inserting hardware on panels of varying sizes without the need for any special setup. Automatic drilling machine for processing spatula handles, knife handles, paintbrush handles, and other similar items. The machine has an automatic loader and a high precision rotary… As the cost of power tools and appropriate electric motors has decreased, such attachments have become much less common.

Our side hole machine has the same configuration as the feeder. Even though it is only to punch side holes and pull side grooves, accuracy and efficiency are required. The probe brand, bed structure, and accessories used are all very large. The compact design, which takes up little space, makes these tools ideal for a small furniture workshop. Guangdong SANDAR CNC Machinery Co., Ltd. was founded in 1995.

Composition of Drill Levers

Levers attached to one side of the head are used to change the spindle speed by selecting different gear ratios, usually in conjunction with a two- or three-speed motor. Most machines of this type are designed to run on three-phase electricity and are generally more durable than equivalently sized belt-driven units. Almost all of the examples use geared racks to adjust the table and head position on the column.

Basic IntelliGuide High-speed drilling and dowel insertion aggregate provide accurate drill holes and precise positioning of dowels. Ideal for vertical drilling in the border area… A hole saw is a large drill bit with a jagged edge that is used to cut large holes. Drills are used in surgery to remove or create holes in bone; dental, orthopaedic, and neurosurgery are among the specialities that use them. To maintain accuracy and momentum, it is made up of a vertical spindle aligned by a piece of horizontal wood and a flywheel.

Coolant systems are also common on these machines to extend tool life in production. A CNC six-sided drilling machine is an automatic high-end hole-arranging machine used in the production of panel furniture. It can achieve six-sided positioning and front and back groove processing at the same time using wireless scanning, automatic positioning, double-clamp automatic clamping, automatic loading, and processing. Following completion, the clamp will automatically load the board into the sorting rotary platform, which has a high degree of automation and machining efficiency.

The machines drill precise blind holes into chipboard, slats, beams, or solid wood. Extraction reliability is a key feature of efficient dowel hole drilling machines. This keeps the chips flying around the machine from falling back into the blind hole, making the dowel inserting machine’s job more difficult. First and foremost, do your best to select a reputable CNC drilling machine manufacturer. Only the best CNC machinery can offer you the best CNC drilling machine and the best after-sales service.